- Home

- Products +

- Industries +

- About Us +

- News

- Contact Us

- Home

- Products

- Industries

- About Us

- News

- Contact Us

Polyethylene Oxide(PEO) is a nonionic water-soluble thermoplastic resin with properities that include excellent coagulation,binding effect, thickening, and friction reduction.

Polyethylene Oxide(PEO) is obtained through the heterogeneous polymerzation of ethylene oxide(CH2CH2O)N, which in turn creates poly(ethylene oxide) or PEO.

Polyethylene Oxide(PEO) is a high-polymer polyethylene oxide with high molecular weights ranging from 150,000 to 10 million, which is created from the polymerzation of ethylene oxide.

Polyethylene Oxide(PEO) can be used in a wide range of applications, can meet specific formulation and processing requirements.

Specifications

Specification | |

Chemical Name | Polyethylene Oxide Powder |

Appearance | White Powder |

PH value, 25℃,1% | 7-9 |

Mesh 20, | 100% |

Mesh 40 | ≥90% |

Dry loss,105℃, wt% | ≤1.5% |

Ash content,wt% | ≤0.5% |

Epoxypropane,mg/kg | 0.5max |

Antioxidant,mg/kg | 0.15max |

MW,D | 15,000-6,000,000 |

Pb content, mg/kg | ≤0.03 |

MI (g/min) | 40 |

Application Range

Ceramic, Glass, metallurgy, Chemical

Textile ,Dye and Paint

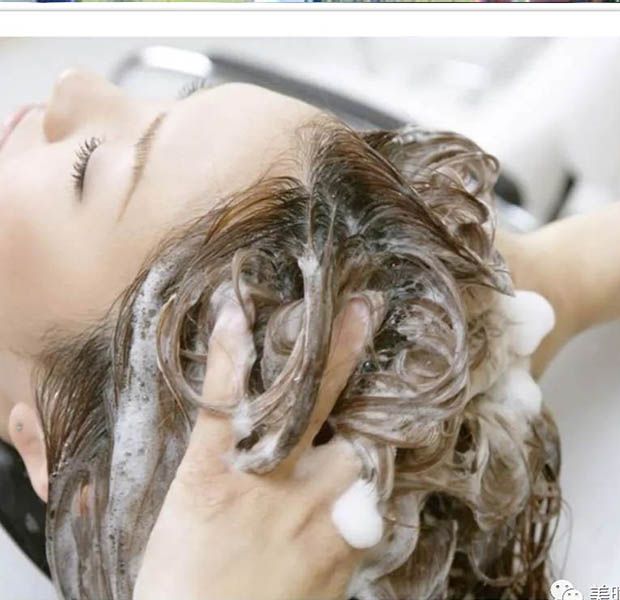

Daily chemical

cleaning agent

Paper Making

Key Properties

General Properties

1. Water-soluble thermoplastic resin,so PEO can be used for extrusion molding, foundry molding, and calendaring molding.

2. Also soluble in various organic solvents, can forms associated molecules with chemical compounds with high polarity such as urea, acrylic resin, and phenoi resin.

3. Non-ionic.

4. When dissolved, the solution show high viscosity even at low density, making PEO an effective thickener.

5. Products with high-molecular weights are viscoelastic,so their aqueous solutions can reduce spattering and misting, and have dispersing and coagulation properties.

6. Can’t be broken down by bacteria.Films of PEO are flexible, tough and resistant to most oils and greases.

7. Aqueous solution reduces friction resistance.

Function including as follows,

1. Film Former-

Resistant to oil and greases; Compatible with other resins and plasticizing agents.

2. Wet Tack- Sticky wet adhesives; Non-tacky when dry.

3. High Binding Efficiency--Outstanding binder for inks, pigments, ceramics, metal powders, fillers and more; Burns off clean at low temperatures

4. Cross-linkable-- Can form highly water-retentive gels by irradiation without initiators or co-agents.

5. Flocculant--Adheres onto colloidal materials;Efficiently separates fines from aqueous systems.

6. Viscoelasticity--Reduces splattering; Controls drift and misting when sprayed;Pituitous.

7. Lubricity-Super ability the lubricity,reduce the most friction.

8. Thermoplasticity--Readily extruded, calendared, injection-molded or cast; Heat-sealable and orientable.

9. Froms Novel Complexes--Associates with polar compounds such as phenolic resins, mineral acid, urea,etc.

10. Sulubility in Organic Solvents--Thickens ketons, alcohos, esters and some hydrocarbons; Not generally soluble in glycols, diols and aliphatic ethers.

11. Low Toxicity--Pooly absorbed and non-irritant

12. Drag Reduction-- Concerves energy by reducing turbulent friction for fluids

13. Thickening--Large range of viscosities that can be customized; Compatile from pH 2 to 13; Non-ionic and pseudoplastic.

Packaging and Storage

A. Standard Packing:In 20kg/barrel.

B. Standard Packing:in 15kgs carton inner PE bags.

C. Standard Packing: In 20kg/ bags inner PE bags

Big Bag or other special packages are possible on request.

Store it in a cool, dark place away from direct sunligh, rain, dew , high humidity and heat resources. The temperature in the storage area should not exceed 30℃.

If PEO powder spills onto the floor and gets wet, it will become very slippery, so need to pay attention when working around split PEO.

Safety Notes

The above data is in accordance with our knowledge, but don’t absolve the clients carefully checking it all immediately on receipt. To avoid the different formulation and different raw materials, please do more testing before using it. We reserve the right to alter our product and without informing in advance.

E-mail: sdcharing@sdcharing.com

Phone: +86 131 7667 0070

WhatsApp: 8613176670070

Add.: Jinan City, Shandong Province, China